More Information

High Temperature Weldable Strain Gauge

AW series High temperature Weldable strain gauge

These strain gauges have strain sensing elements fully encapsulated in corrosion-resisting metal tubes (except for AW-6). They are suited to use in various environment including in liquids or gases. Installation is easily done using dedicated spot welder W-50R/W-50RB

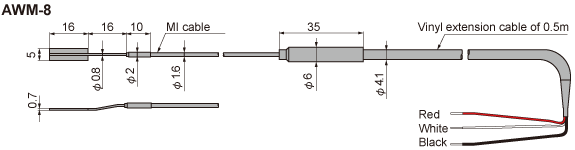

AWM-8 Quarter bridge with 3-wire system

The AWM is usable up to 300℃ for both static and dynamic measurement. The backing material is available in Inconel 600 or SUS304 which should be selected according to the test specimen material.

| Main object material | Metal |

|---|---|

| Operational temperature | -196 to +300℃ |

| Temperature compensation range | RT to +300℃ |

| Bonding adhesive | Spot welding (TML spot welder W-50R is required) |

| Backing | Inconel 600, SUS304 |

| Element | Special alloy |

| Strain limit | 1% (10000 x 10-6 strain) |

| Fatigue life at room temperature | 1×106 (±1000×10-6 strain) |

-

Specifications

Type Gauge

length

(mm)Gauge base Test specimen Resistance in (Ω) Dimensions

(mm)Materials AWM-8-1A-2-11.0 8 L16 x W5 x T0.7 Inconel 600 Mild steel 120 AWM-8-1B-2-17.0 SUS304 Stainless Each package contains one strain gauge.

Other cable length available on request

(Made to order by every 1 m for MI cable and by every 0.5 m for vinyl cable)

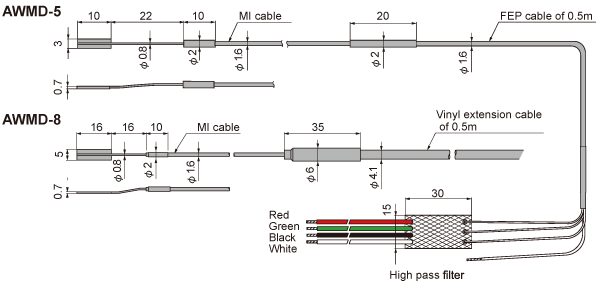

AWMD-5, AWMD-8 (for dynamic measurement only : -196 to +800℃) Full bridge

The AWMD is applicable up to 800°C and is dedicated to dynamic measurement. A high pass filter is a standard accessory. Using the high pass filter, unnecessary direct current component and low frequency component (thermal output, drift, etc.) are cancelled. A DC exciting dynamic strainmeter such as DC-96A/DC-97A, smart strain recorder such as DC-204R, or multi-recorder TMR-200 series should be used for the measurement.

| Main object material | Metal |

|---|---|

| Operational temperature | -196 to +800℃ |

| Temperature compensation range | - |

| Bonding adhesive | Spot welding (TML spot welder W-50R is required) |

| Backing | Inconel 600 |

| Element | Special alloy |

| Strain limit | 1% (10000 x 10-6 strain) |

| Fatigue life at room temperature | 1 to 106 (±1000 x 10-6 strain) |

-

Specifications

Type Gauge

length

(mm)Gauge base Test specimen Resistance in (Ω) Dimensions (mm) Material AWMD-5-AKM-2(6F)-1.6Hz 5 L10 x W3 x T0.7 Inconel 600 Inconel 600 equivalent 60 AWMD-8-A-2-1.6Hz 8 L16 x W5 x T0.7 120 Each package contains one strain gauge.

Other cable length available on request

(Made to order by every 1 m for MI cable and by every 0.5 m for vinyl cable)

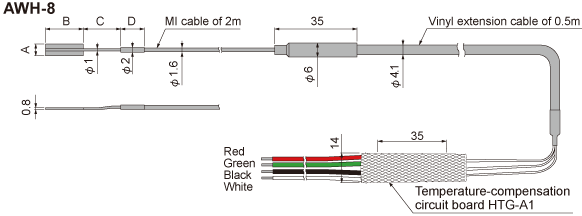

AWH-4/AWH-8 Full bridge

The backing material is available in Inconel 600 or SUS304 which should be selected according to the test specimen material. Although it has half bridge construction consisting of active and dummy gauges, the measurement is made by full bridge method using the supplied temperature compensation circuit board. The maximum operational temperature is 600°C for static measurement and 650°C for dynamic measurement.

| Main object material | Metal |

|---|---|

| Operational temperature | Static: -196 to +600℃ Dynamic: -196 to +650℃ |

| Temperature compensation range | Static: RT to +600℃ Dynamic: - |

| Bonding adhesive | Spot welding (TML spot welder W-50R is required) |

| Backing | SUS304 or Inconel 600 |

| Element | Special alloy |

| Strain limit | 0.6% (6000 x 10-6 strain) |

| Fatigue life at room temperature | 1 x 106 (±1000 x 10-6 strain) |

-

Specifications

Type A B C AWH-4 3 10 8 AWH-8 5 16 16 Type Gauge

length

(mm)Gauge base Test specimen Resistance in (Ω) Dimensions (mm) Materials AWH-4-7A-2-11.0 4 L10 x W3 x T0.8 Inconel 600 Mild steel 60 AWH-4-7B-2-17.0 SUS304 Stainless AWH-8-7A-2-11.0 8 L16 x W5 x T0.8 Inconel 600 Mild steel 120 AWH-8-7B-2-17.0 SUS304 Stainless Each package contains one strain gauge.

Other cable length available on request

(Made to order by every 1 m for MI cable and by every 0.5 m for vinyl cable)

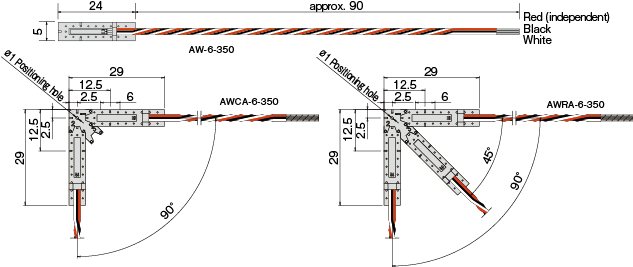

AW-6-350/AWCA-6-350/AWRA-6-350 Quarter bridge with 3-wire system (G.F. 2.1 approx.)

This gauge has corrosion-resisting stainless steel base with thickness of 0.08 mm. It is easily installed by using a dedicated spot welder W-50RC.

It is suited to strain measurement up to 300°C, measurement of specimen to which adhesion is not applicable, and/or long term measurement.

| Main object material | Metal |

|---|---|

| Operational temperature | -196 to +300℃ |

| Temperature compensation range | +10 to +100℃ |

| Bonding adhesive | Spot welding (TML spot welder W-50R is required) |

| Backing | SUS304 |

| Element | Special alloy |

| Strain limit | 0.5% (5000 x 10-6 strain) |

| Fatigue life at room temperature | 1 x 106 (±1000 x 10-6 strain) |

-

Specifications

Leadwire used ø0.2 fluorinated resin (PTFE) leadwire 0.1m

Type Element Gauge

length

(mm)Gauge base Test specimen Resistance in (Ω) Dimensions (mm) Material AW-6-350-11-4FB01LT Single-element 6 L24 x W5 SUS304 Mild steel 350 AWCA-6-350-11-4FB01LT 2-element 6 L29 x W29 AWRA-6-350-11-4FB01LT 3-element 6 L29 x W29 Each package contains 5 strain gauges.

Other cable length available on request

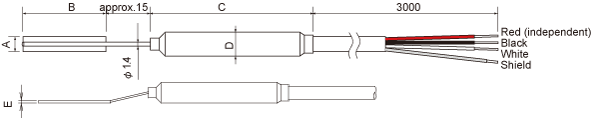

AWC-8B Quarter bridge with 3-wire method (G.F. 2.1 approx.)

These strain gauges have hermetically sealed construction with the sensing element encapsulated in the stainless steel tube. This construction helps to simplify the coatings for moisture and water proofing, and the strain gauges are suited to strain measurement for long term and/or in harsh environment.

| Main object material | Metal |

|---|---|

| Operational temperature | -20 to +100℃ |

| Temperature compensation range | AWC-8B: +10 to +100℃ |

| Bonding adhesive | Spot welding (TML spot welder W-50R is required) |

| Backing | SUS304 |

| Element | Special alloy |

| Strain limit | 0.5% (5000 x 10-6 strain) |

| Fatigue life at room temperature | 1 x 106 (±1000 x 10-6 strain) |

-

Specifications

Leadwire used AWC-8B: ø5 0.3mm2 shielded 3-core vinyl leadwire

Type A B C D E AWC-8B-11-3LTSB 5 28 55 Φ8 1 Type Gauge

length

(mm)Gauge base Test specimen Resistance in (Ω) Dimensions (mm) Material AWC-8B-11-3LTSB 8 L28 x W5 x T1 SUS304 Mild steel 120 Each package contains one strain gauge.

Other cable length available on request