Errors occur with general measurement

A Wheatstone bridge circuit is generally used in measurement by a strain gauge, and strain is found by converting the change in resistance of the strain gauge to an electric signal. In measurement with a bridge circuit, error from initial imbalance of the 4 bridge resistors and error from nonlinearity particular to a bridge circuit. Our original “complete correction method for strain” is a revolutionary correction method that eliminates these errors in the quarter-bridge method, using only output voltage and is unaffected by the resistance values of a strain gauge or dummy resistance.

Automatic correction of initial bridge circuit imbalance

Our original “complete correction method for strain” has the following features.

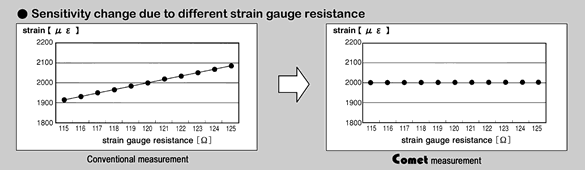

- Initial imbalance with scattered strain gauge resistance values assumes a zero value, and the gauge factor becomes constant (strain gauge with unequal resistance values).

- Measurement is no longer affected by shifts in initial imbalance from changes in resistance when a strain gauge is adhered to a curving surface.

- Initial lead wire resistance imbalance value is no longer affected.

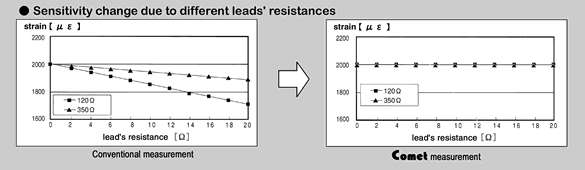

- Automatic correction of decrease in sensitivity due to resistance value change with extension of lead wire

- Automatic correction of resistance value change due to temperature of lead wire

- Automatic correction of dummy resistance consisting of a quarter bridge within the measuring instrument

For example- Extending the lead wire during strain measurement

- The gauge is adhered to a curving surface

- Using strain gauges with unequal resistance values

- Measurement is easily affected by temperature

- Adhering different gauges as a test

- Measuring after reobtaining the initial value

Example of complete correction method for strain in use

An example of measurement results obtained with a general strain gauge and measurement results using our original “complete correction method for strain“ is shown below.

Using TDS-630, thermal output accompanying change in temperature is automatically corrected, allowing actual strain to be measured in real time. By setting individual thermal output formulae (thermal output characteristics) in the data logger TDS-630 beforehand, thermal output accompanying change in ambient temperature during measurement is automatically corrected, and enhances measurement accuracy. (Thermal output formulae are given on the data sheet included with the strain gauge)

“Complete correction method for strain” is only installed standard with our data loggers and switching boxes, and is not sold as software.

More Information