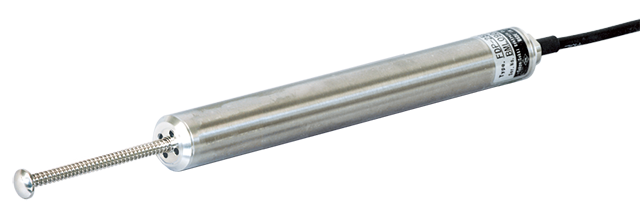

Transducer Related Product

Transducer Related Product

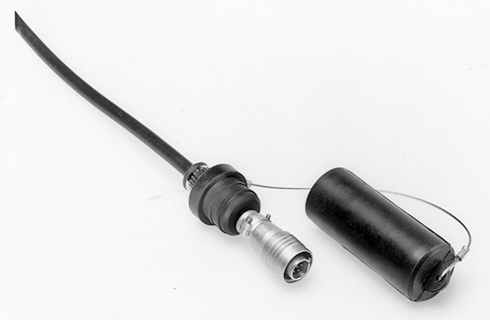

Cable Connector Cap BC-9 / BC-9A

To protect the connectors from dust and water droplets, such as advanced cable converter.

| Type | Notes |

|---|---|

| BC-9 | ø9mm Cable only |

| BC-9A-1 | ø9mm 0.5mm2 4-core shielded chloroprene cable 1m NDIS Plug or long with loose end |

Cable Cap

Tip to protect it from dust and water droplets, such as cable converter.

The following eight types of the diameter of the cable.

| Cable Cap | ø2.4mm ø3mm ø4.6mm ø6mm ø7mm ø9mm ø11.5mm ø16.5mm |

|---|

Joint Kit

When coating is to extend the cable kit.

We gathered the materials I need to protect cable connections will facilitate joint work.

Instrumentation Cable

Used to extend the Civil Engineering Transducer cable.

| Type | Names | Coating diameter | 1m length |

|---|---|---|---|

| CT6-4V100 | ø6mm 0.3mm2 4-core shielded vinyl cable |

6mm | 100m |

| CT6-4N100 | ø6mm 0.35mm2 4-core shielded chloroprene cable |

6mm | 100m |

| CT9-4N100 | ø9mm 0.5mm2 4-core shielded chloroprene cable |

9mm | 100m |

| CT11.5-4N100 | ø11.5mm 0.5mm2 4-core shielded chloroprene cable |

11.5mm | 100m |

| CT9-5N100 | ø9mm 0.3mm2 5-core shielded chloroprene cable |

9mm | 100m |

| CT11.5-5N100 | ø11.5mm 0.5mm2 5-core shielded chloroprene cable |

11.5mm | 100m |

Transducers cable

| 4-core shielded chloroprene cable ø9mm 0.5mm2 | |||

|---|---|---|---|

| Type | Length | type | |

| CT9-4N0.5/NJ-STB | 0.5m | NDIS Jack to Long with loose end | |

| CT9-4N10/NP-STB | 10m | NDIS Plug to Long with loose end | |

| CT9-4N2/WP-NP | 2m | Waterproof plug to NDIS Plug | |

| CT9-4N5/WP-NP | 5m | Waterproof plug to NDIS Plug | |

| CT9-4N10/WP-NP | 10m | Waterproof plug to NDIS Plug | |

| CT9-4N20/WP-NP | 20m | Waterproof plug to NDIS Plug | |

| CT9-4N30/WP-NP | 30m | Waterproof plug to NDIS Plug | |

| CT9-4N2/WP-STB | 2m | Waterproof plug to Long with loose end | |

| CT9-4N5/WP-STB | 5m | Waterproof plug to Long with loose end | |

| CT9-4N10/WP-STB | 10m | Waterproof plug to Long with loose end | |

| CT9-4N20/WP-STB | 20m | Waterproof plug to Long with loose end | |

| CT9-4N30/WP-STB | 30m | Waterproof plug to Long with loose end | |

| 2-core shielded vinyl cable φ6mm 0.5mm2 | |||

|---|---|---|---|

| Type | Length | type | |

| CT6-2R2/WP-STB | 2m | Waterproof plug to Long with loose end | |

| 4-core shielded chloroprene cable φ6mm 0.35mm2 | |||

|---|---|---|---|

| Type | Length | type | |

| CT6-4N10/WJ-STB | 10m | Waterproof jack to Long with loose end | |

| 4-core shielded vinyl cable φ6mm 0.3mm2 | |||

|---|---|---|---|

| Type | Length | type | |

| CT6-4V0.5/NJ-STB | 0.5m | NDIS Jack to Long with loose end | |

| CT6-4V5/NJ-STB | 5m | NDIS Jack to Long with loose end | |

| CT6-4V10/NJ-STB | 10m | NDIS Jack to Long with loose end | |

| CT6-4V20/NJ-STB | 20m | NDIS Jack to Long with loose end | |

| CT6-4V30/NJ-STB | 30m | NDIS Jack to Long with loose end | |

| CT6-4V5/NJ-NP | 5m | NDIS Jack to NDIS Plug | |

| CT6-4V10/NJ-NP | 10m | NDIS Jack to NDIS Plug | |

| CT6-4V20/NJ-NP | 20m | NDIS Jack to NDIS Plug | |

| CT6-4V30/NJ-NP | 30m | NDIS Jack to NDIS Plug | |

| CT6-4V5/NP-STB | 5m | NDIS plug to Long with loose end | |

| CT6-4V10/NP-STB | 10m | NDIS plug to Long with loose end | |

| CT6-4V10/NP-NP | 10m | NDIS plug to NDIS plug | |

| CT6-4V3/SNP-STB | 3m | Special plug to Long with loose end | |

| 4-core shielded fluorinated resin (FEP) cable φ4mm 0.08mm2 | |||

|---|---|---|---|

| Type | Length | type | |

| CT4-4F5/SNP-STB | 5m | Special plug to Long with loose end | |