Instrument Overview

Strainmeters are connected to strain gauges and strain-gauge type transducers in order to take measurements. A strain gauge generates changes in resistance that are proportional to the amount of strain applied to it, and it operates on the principle that the amount of strain can be determined by measuring the amount of changes. However, these changes must be electrically amplified in order to measure them because they are so small. This is the purpose of strainmeters, and TML offers a wide range of such meters that vary in measurement output method, frequency response, usage, shape and functions. TML strainmeters not only measure strain, but are fully capable of measuring voltage and temperature as well.

STATIC STRAIN and DYNAMIC STRAIN

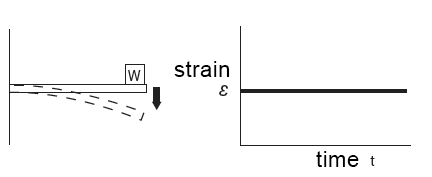

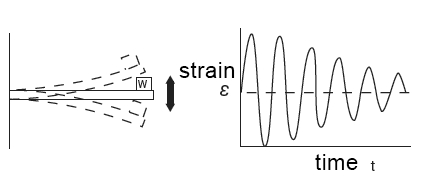

Strain which changes in only a small amount with the passage of time is called “static strain”, and strain which changes quickly in the same regard is called “dynamic strain”. Strainmeters comprise static strainmeters with a goal of measuring static strain, and dynamic strainmeters with a goal of measuring dynamic strain. Our data loggers are representative of static strainmeters. However, data loggers have also recently appeared which are able to capture comparatively quick occurrences as static strainmeters. Dynamic strainmeters exist in digital-type instruments as well as standard analog types. Instruments are also available for measuring histograms, or frequency distributions, of dynamic occurrences, such as histogram recorders.

STATIC STRAIN

Instances where measured amounts of strain do not change or change very gradually with time.

DYNAMIC STRAIN

Instances where measured amounts of strain change quickly with time.

These include instances where vibrational occurrences change sinusoidally at a certain frequency.

Technical Terms

- Number of Measuring Points

- Number of points that can be measured with an instrument.

Points that can be switched to and measured on a static strain meter such as a data logger or switching box.

With a dynamic strainmeter, points that can be measured at the same time (number of channels). - Applicable Gauge Resistance

- Resistance value for a strain gauge capable of measurement (or strain gauge-type transducer).

- Bridge Excitation

- With strainmeters, the differentiation between voltage or current, and then direct current and alternating current of power supplied to a bridge circuit. With instruments supplying bridge excitation as a pulse, indicates the pulse width. Where the bridge excitation is by alternating current, indicates the frequency.

- Measuring Speed

- Time required for measuring 1 point with a data logger.

- Sampling Speed

- Speed at which occurrences are digitized continuously with a dynamic digital instrument.

- Balancing Range

- The range in which an initial imbalance value can be adjusted with an instrument.

On a carrier wave-type instrument using alternating current as the bridge excitation, the capacity value as well as the resistance value. - Balancing Accuracy

- The accuracy of balancing adjustment. Displayed converted to an input strain value, etc.

- Measuring Range

- The range in which measuring is possible while satisfying specifications.

- Initial Value Storing Range

- Range in which an initial value can be stored.

- Sensor Mode

- Category of object being measured and settings, such as the method for measuring strain (quarter bridge, full bridge, etc.) and type of thermocouple when measuring temperature.

- Frequency Range

- Frequency range in which response can be gained and in which output satisfies specifications with regard to input which is changed to a sine wave. Displayed with a frequency with output of -3 dB (about 70% of output).

- Measuring Mode

- Method of processing measured values on a data logger. Measuring mode can be initial-in measurement, direct measurement, or “measure” measurement.

Initial-in measurement:

An initial imbalance value (also called initial value) exists even in a no-load state with strain measurement. This value is measured and stored.

Direct measurement:

A measured value is measured as it is and output (a value including the initial imbalance value, called a direct value).

“Measure” measurement:

Output after subtracting the stored initial value from the direct value. Accordingly, the change from the initial value is measured. - Accuracy

- Limit value for error under specified conditions.

Expressed as a percentage (%rdg or %FS) with regard to a reading value or measurement range. rdg = reading, FS = Full Scale (measurement range). - Resolution

- The smallest amount of a change that can be measured.

- Non-linearity

- With the output of an amplifier or the indicated value of an indicator, the maximum deviation of a measured curve with regard to a line joining a start point and the largest output value. Displayed as a percentage with regard to the maximum measured value.

- Stability

- Change in zero point or sensitivity with a change in temperature, time, etc.

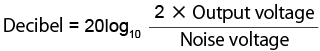

- Signal to Noise Ratio

- Ratio of specified output and noise for a set sensitivity. Displayed in decibels (dB).

- Sensitivity

- Output (voltage, current, display value, etc.) with regard to input under specified conditions.

- Operating Temperature and Humidity Range

- Range of temperature and humidity in which an instrument can be used while satisfying specifications.