Standard connection method

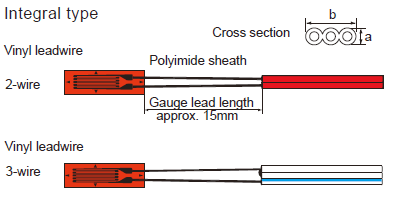

Integral type

A vinyl leadwire is jointed to the polyimide sheathed gauge leads of a strain gauge. The solder joints are covered with the vinyl sheath of the leadwire. This is our standard method of integral leadwire attachment.

| Leadwire | ||||

|---|---|---|---|---|

| Constrution | Dimension (mm) | |||

| a | b | |||

| 2-wire paralleled | LJB/LJB-F | 7/0.12 | 1.1 | 2.2 |

| LJC/LJC-F | 10/0.12 | 1.4 | 2.8 | |

| 2-wire twisted | LH/LH-F | 5/0.07 | 0.4 | - |

| 3-wire paralleled | LJBT/LJBT-F | 7/0.12 | 1.1 | 3.3 |

| LJCT/LJCT-F | 10/0.12 | 1.4 | 4.2 | |

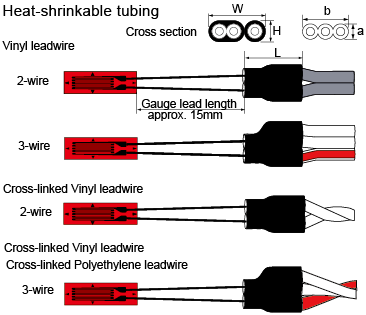

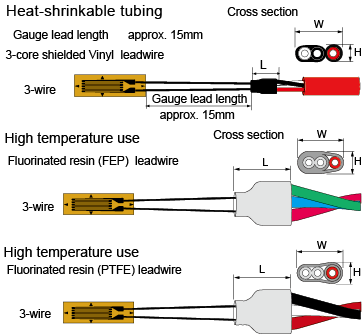

Heat-shrinkable tubing

The soldered joint between the gauge leads and the leadwire is protected with a heat shrinkable tube. The heat shrinkable tubes are available in three temperature ratings of 80℃, 200℃ and 260℃.

| Leadwire | Heat-shrinkable tube | ||||||

|---|---|---|---|---|---|---|---|

| Constrution | Dimension (mm) | Dimension (mm) | |||||

| a | b | L | H | W | |||

| 2-wire paralleled | LJD | 12/0.18 | 1.9 | 3.8 | 11 | 3 | 6 |

| 3-wire paralleled | LJDT | 12/0.18 | 1.9 | 5.7 | 11 | 3 | 7 |

| 3-wire twisted | LHT/LHT-F | 5/0.07 | 0.4 | - | 5 | 0.8 | 1.6 |

| Cross-linked vinyl 2-wire twisted | LJRA/LJRA-F | 7/0.16 | 0.9 | - | 11 | 2 | 4 |

| Cross-linked vinyl 3-wire twisted | LJRTA/LJRTA-F | 7/0.127 | 1.1 | - | 11 | 2 | 4 |

| Cross-linked polyethylene 3-wire twisted | LJQTA/LJQTA-F | 7/0.127 | 0.8 | - | 11 | 2 | 4 |

| 3-wire twisted | LTSA/LTSA-F | 7/0.12 | Φ3.0 | 10 | 2 | 4 | |

| LTSB/LTSB-F | 7/0.26 | Φ5.0 | 12.5 | 3 | 6 | ||

| FEP (Fluorinatedethylene-propylene) 3-wire twisted | 6FB_LT/6FB_LT-F | 1/0.2 | Φ1.1 | 11 | 2 | 2 | |

| 6FAS_LT/6FAS_LT-F | 7/0.18 | Φ2.0 | 11 | 3 | 4 | ||

| PTFE (Polytetrafl uoroethylene) 3-wire twisted | 4FB_LT/4FB_LT-F | 1/0.2 | Φ1.1 | 11 | 2 | 2 | |

| 4FA_LT/4FA_LT-F | 7/0.16 | Φ1.9 | 11 | 2.5 | 4 | ||

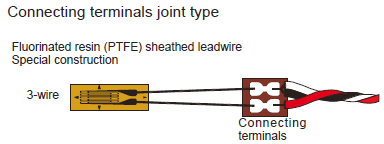

Connecting terminals joint type

The gauge leads and the leadwire are jointed using a foil shape connecting terminal. Measurement in high temperature is possible by using a high temperature solder with melting point of 300℃ or more for the joint.

| Leadwire | |||

|---|---|---|---|

| Constrution | Dimension (mm) | ||

| PTFE(Polytetrafluoroethylene) 3-wire twisted | 4FB_LT/4FB_LT-F | 1/0.2 | Φ1.1 |

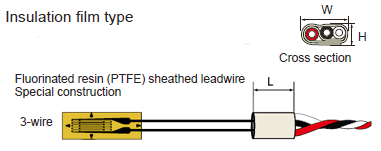

Insulation film type

The soldered joint between the gauge leads and the leadwire is covered with an insulation film of glass cloth base. The film is resistive to heat up to 300℃, so this method is suited to measurement in high temperature.

| Leadwire | Film | |||||

|---|---|---|---|---|---|---|

| Constrution | Dimension (mm) | Dimension (mm) | ||||

| L | H | W | ||||

| PTFE (Polytetra-fluoroethylene) 3-wire twisted | 4FA_LT/4FA_LT-F | 7/0.16 | Φ1.9 | 13 | 1.5 | 4 |

More Information