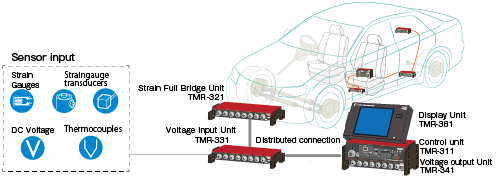

Instrument serving as the hub of an in-vehicle measurement system

The multi-recorder TMR series is a compact multi-channel data recording system that can easily combine measurement units for all sensor inputs depending on the purpose. Because of its small size and light weight, it is ideal for in-vehicle measurement with limited installation space. In automobile measurement, there are a number of test items such as running performance evaluation test, operability, ride comfort, and safety, using many sensors. Multi-recorder systems have a variety of measurement units that meet these needs.

Features

- DC drive, perfect for in-vehicle use

- Vibration-resistant and compact, suitable for in-vehicle use

- Controllable from display unit or tablet PC

- High-resolution 0.1 × 10-6 strain mode

- Up to 80 measurement points

- 100-kHz high-speed sampling

- USB and LAN interfaces

- Recording of voltage outputs from dedicated measuring instruments such as six-component force transducer

- Accepts 32 GB SD card

- Auto data save at momentary power stop and auto restart at power restoration

- Accommodates a distributed arrangement, allowing distributed storage in narrow places

Small and lightweight instruments suitable for small-scale measurement and limited installation space

DC-204R/DC-204Ra are CF card-recording dynamic strain meters that measure strain, DC voltage, and thermocouple temperature.

The DC-204Ra features analog output (±5 V) and can output waveforms to external recorders and automotive ECUs.

Up to 8 units and 32 channels can be combined using the standard-supplied dedicated software/controller DC-7204.

Features

- 4 channels, compact 84 (W) × 42 (H) × 157 (D)

- 200-kHz sampling (in 1-channel mode at maximum speed)

- Simultaneous 4-channel sampling at 50 kHz

- Large strain can be measured up to 80,000 μ-strain (using 0.5-V carrier)

- CF cards up to 2 GB supported, for saving a large volume of data

- Auto data protection (UPS) for power outages, enabling stop of measurement, saving of data, and power shutdown in the event of an unexpected power down

- Measured data compatible with DADiSP format

- External start/stop, external trigger

- Sensor open check function

- USB interface, bundled control software

Selecting strain gauges for automotive, aircraft, industrial machinery, and small strain gauge applications

Our strain gauges are used as a direct measure of the strength of the object being measured. In keeping pace with such applications amid increasingly more sophisticated technology, we have introduced newer and smarter sensors to our lineup. This section introduces a variety of applications in which we have garnered achievements in the automotive, aircraft, and industrial machinery fields, illustrating subjects of measurement and goals. Contact us when making a specific measurement plan, and we will provide details such as how to select and install strain gauges, adhesives, etc.

Ultracompact strain gauges Selection of strain gauges for strain measurement in extremely small locations

Automobiles, personal computers, industrial machinery, and other components require miniaturized printed circuit boards and mounted parts. As a strain gauge for directly measuring their mechanical properties, we have developed a lineup of ultracompact strain gauges that can be installed in a smaller area.

Ultracompact strain gauges

Selecting strain gauges for shear strain and torque measurement

Measure strain occurring at 45 degrees caused by shear stress. Since the gauge size is small, it can be applied to thin springs. The polyimide base allows measurement at temperatures up to +200℃. A standard specification for a coefficient of thermal expansion of 11 × 10-6/℃ is available. We also make self temperature compensated strain gauges according to the coefficient of thermal expansion of other materials.

Strain gauges for shear strain and torque measurement

Selecting strain gauges for stress concentration measurement

A strain gauge with a short gauge length is structured with 5 elements in a row on the gauge backing in order to measure stress concentration. There are two types of gauges (X and Y types), depending on the axial direction of the gauge and the arrangement of the 5 elements, as well as two-element gauges where the two types are in a stacked arrangement. F series gauges allow measuring up to +80℃ and QF series up to +200℃.

Strain gauges for stress concentration measurement

Selecting strain gauges for axial force measurement

FLK type, designed with a narrow gauge width, is suitable for adhering axially along bolt shafts, thin pipes, and round bars. Selection can be made from the F, QF, and ZF series depending on the environment it will be used in. QF- and ZF-series standard specifications for a coefficient of thermal expansion of 11 × 10-6/℃ are available. Self-temperature compensating gauges are also manufactured to match the linear expansion coefficient of other materials.

Strain gauges for axial force measurement

Ultracompact strain gauges Selection of strain gauges for strain measurement in extremely small locations

Automobiles, personal computers, industrial machinery, and other components require miniaturized printed circuit boards and mounted parts. As a strain gauge for directly measuring their mechanical properties, we have developed a lineup of ultracompact strain gauges that can be installed in a smaller area.

Ultracompact strain gauges

Selecting strain gauge for residual stress measurement

Strain gauges are available for measuring the residual stress of parts by fully open and partially open methods.