Technical Terms

-

Gauge Length

-

This dimension represents the actual grid length in the sensitive direction.

-

Gauge Resistance

-

The gauge resistance is the electrical resistance of an unbonded gauge at room temperature and subject to no external stress.

-

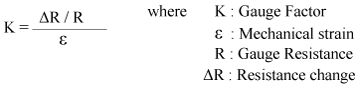

Gauge Factor

-

The amount shown in the following equation is called the gauge factor. In this equation, ε indicates the strain generated due to uniaxial stress in the direction of the strain gauge axis. ΔR/R shows the ratio of resistance change due to strain ε.

-

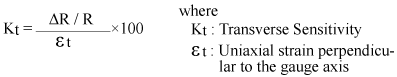

Transverse Sensitivity

-

The gauge also exhibits sensitivity in the direction perpendicular to the axial direction. The amount shown in the following equation due to the uniaxial strain (εt) in the direction perpendicular to the gauge axis, and the resistance variation generated thereby, is called transverse sensitivity (Kt).

-

Temperature Compensation Range

-

The temperature range within which thermal output meets a specification with a self temperature compensated gauge.

-

Self Temperature Compensated Gauge

-

A strain gauge made so that thermal output is as little as possible when adhered to a material to be measured with a particular coefficient of thermal expansion within a specified temperature range. We term self temperature compensated gauges of within ±1.8 × 10−6 strain per 1℃ capability a self temperature compensated gauge.

-

Operating Temperature Range

-

This range is the temperature range within which a strain gauge can be used continuously under appropriate conditions.

-

Strain Limit

-

The strain limit is the maximum amount of strain under which a strain gauge can operate under a given condition without suffering damage.

-

Fatigue Limit

-

The number of times a certain amount of strain is applied mechanically to an adhered strain gauge until change of 100×10−6 strain with regard to an initially indicated strain is observed.

Strain gauge shapes

Strain gauges are available in shapes suitable for any application.

Select a gauge shape that meets measuring goals.

| Number of elements | 1 element | 2 elements | 2 elements |

|---|---|---|---|

| Shape |  |

|

|

| Name | Single-element | Cross | Cross |

| Arrangement | ‐ | Stacked | Plane |

| Number of elements | 3 elements | 3 elements | 5 elements |

| Shape |  |

|

|

| Name | Rosette | Rosette | 5-element |

| Arrangement | Stacked | Plane | ‐ |

Selecting a gauge length

Measurement object

As required by the object being measured, a short-length strain gauge may be used for localized strain measurement, and a long-length strain gauge for averaged strain measurement.

Averaged: For nonhomogenous materials, an adequate length of material that allows strain to be averaged is required. To measure nonhomogenous material such as concrete consisting of cement and aggregate, a strain gauge with a length about 3 times that of the aggregate grain size is used.

| Gauge length | Measurement object |

|---|---|

| 0.2 to 1mm | Stress concentration measurement |

| 2 to 6mm | General strain measurement in metal |

| 10 to 20mm | General measurement of mortar, wood, FRP, etc. |

| 30 to 120mm | General measurement of concrete |

Response

The response of a strain gauge depends on the gauge length and the elastic wave (longitudinal wave) of the material being measured.

| Gauge length (mm) | 0.2 | 1 | 3 | 5 | 10 | 30 | 60 |

|---|---|---|---|---|---|---|---|

| Steel | 660 | 530 | 360 | 270 | 170 | − | − |

| Concrete | − | − | − | − | 120 | 50 | 20 |

Gauge width

A narrower-type gauge (FLK type) with the same gauge length is also available. Select a strain gauge with a narrow gauge width for narrow specimens such as pipes and round sticks.

Name of each part of strain gauge

Pictures of each strain gauge given for the strain gauge series are shown enlarged so they are easier to see. Note that they are not shown actual size.