Continuous Tube Displacement Transducer

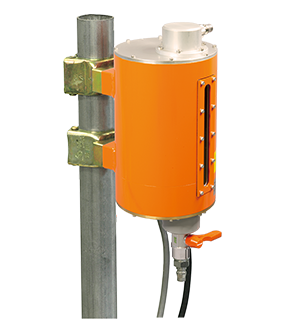

Continuous Tube Displacement Transducer KWL-E 100mm

This displacement transducer measures the vertical displacement of civil engineering structures such as bridges. It is connected to a reference water tank at an immovable point by a connecting pipe, and measures the displacement with respect to the water surface in the tank.

Inside the displacement transducer is a detector that constantly detects and tracks the water surface using a servo mechanism, and a circuit that electrically converts the amount of movement of the detector.

The displacement of the structure is measured as the relative displacement of the reference water surface to the displacement transducer.

Our data logger is used for measurement, allowing automatic measurement of multiple points.

A servo mechanism is used to detect the reference water surface, and the circuit stability has been further improved to ensure stable measurement over a long period of time. (Built-in arrester)

Protection class IP 54 or equivalent

- Features

- Excellent temperature stability

- Drip-proof construction

- Automatic measurement

-

Specifications

Type Capacity Rated output Non-linearity Allowable temperature range KWL-100E 100mm Approx.1mV/V (2000×10-6strain) 0.5%RO 0 to +50℃

(excluding icing)

Continuous Tube Displacement Transducer

Bedrock Displacement Transducer

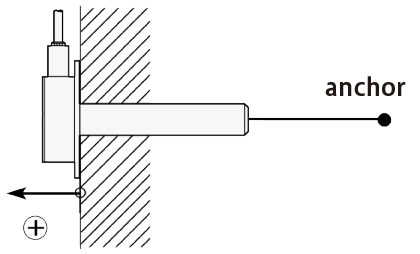

Bedrock Displacement Transducer KLB-B 100mm (-20 to +80mm)

The KLB-B bedrock displacement transducer measures the amount of displacement between the mounting surface and a measuring point in bedrock.

The KLB-B consists of a bedrock displacement transducer KLB-B, a hydraulic anchor (KLF-11/12), and a connecting rod (KLF-21). The KLB-B is equipped with up to 8 displacement transducers, so that 8 hydraulic anchors can be fixed in one borehole (φ66 mm or more for 1 to 6 points, φ86 mm or more for 7 or 8 points) for measurement. The amount of displacement between the displacement transducer and anchor is detected as relative displacement through the rod.

The anchors are anchored to the bedrock by applying water pressure to the anchors at predetermined measuring points in the borehole using a pump from the ground.

Protection class IP 68 or equivalent

- Features

- Remote measurement is possible

- Capable of measuring up to 8 levels of rock displacement

-

Specifications

Type No. of measurement Capacity Rated output Non-linearity Temperature range KLB-100B-○ 1 to 8 100mm

(-20 to +80mm)Approx.2.5mV/V

(5000×10-6strain)0.5%RO 0 to +60℃

(no incing)* “◯” under “Type” corresponds to the number of measurements, 1 to 8.

Type Input/Output Resistance KLB-100B-1 350Ω KLB-100B-2 350Ω KLB-100B-3 350Ω KLB-100B-4 Input resistance 175Ω

Output resistance 350ΩKLB-100B-5 Measurement points1 to 4 Input resistance 175Ω

Output resistance 350ΩMeasurement points5 Input/output resistance 350Ω KLB-100B-6 Input resistance 175Ω

Output resistance 350ΩKLB-100B-7 Measurement points1 to 6 Input resistance 175Ω

Output resistance 350ΩMeasurement points7 Input/output resistance 350Ω KLB-100B-8 Input resistance 175Ω

Output resistance 350ΩOutput polarity

Measurements move in the positive direction with respect to the direction in which the distance between the “rock displacement transducer” and the “water hydraulic anchor” opens

Bedrock Displacement Transducer

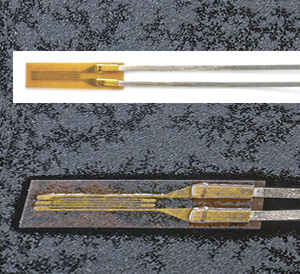

HZF series High temperature use strain gauge

HZF series High temperature use strain gauge

This is an adhesive bonded high-temperature strain gage capable of measuring temperatures up to 35

The lead wires are welded together, making the gauge RoHS compliant.

| Applicable specimen | Metal |

|---|---|

| Operational temperature | -196 to +350℃ |

| Temperature compensation range | +10 to +300℃ |

| Applicable adhesive | C-1, NP-50 |

| Backing | Polyimide |

| Element | Ni-Cr |

| Strain limit | 1%(10000×10-6 strain) |

| Fatigue life at room temperature | 1×106(±1500×10-6 strain) |

-

Single-element

Gauge pattern Type Gauge length

(mm)Gauge width

(mm)Backing length

(mm)Backing width

(mm)Resistance

(Ω)

HZFLA-2-11

HZFLA-2-17

HZFLA-2-232 0.5 5.4 1.4 120 *Each package contains 10 gauges

*Self-temperature compensating gauges for target materials with linear expansion coefficients other than 11×10-6/℃ can also be manufactured. (made-to-order)

Material examples: stainless steel, aluminum alloyPoint:

C-1 adhesives can be used up to 350°C for one short cycle.

For long-term or repeated measurements, please consult with the sales representative in charge.

More Information