Dynamic Measurement Software DC-7630

Dynamic Strain Recorder Measurement Software DC-7630

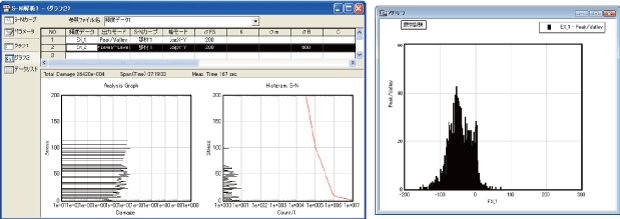

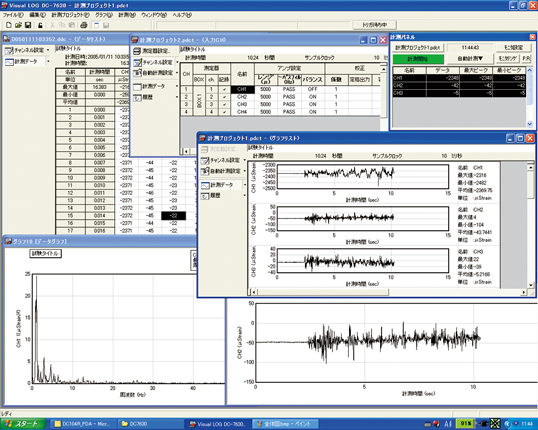

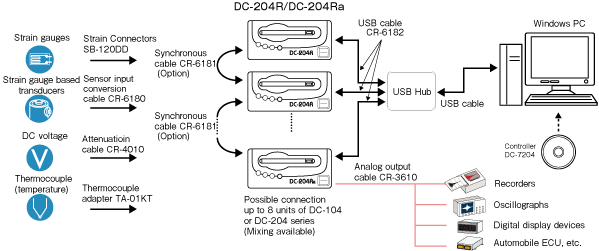

This is measurement software for multichannel dynamic measurement using a compact strain recorder DC-204R, DC-204Ra / DC-104R, or DC-104Ra. Combined use with a recorder DC-204/104 series is possible, with up to 8 units, 32 channels controllable simultaneously. Graph is displayable in real time, allowing measurement while checking a dynamic waveform. Unified management of measurement conditions/settings and data allow settings and measurement data to be viewed on the same screen. Supports CSV format and DADiSP compatible formats for text file conversion of data.

- Features

- DC-204/104 series simultaneous control sampling and data recording

- Up to 8 units, 32 points of sampling and data recording

- Real-time graph display during sampling

- Automatic measurement setting: data trigger measurement, interval measurement, data compilator measurement

- Up to 100 computed points

- Settings for carrying out measurement and measurement results can be managed all together for a measurement project. Can be interfaced onscreen for viewing.

-

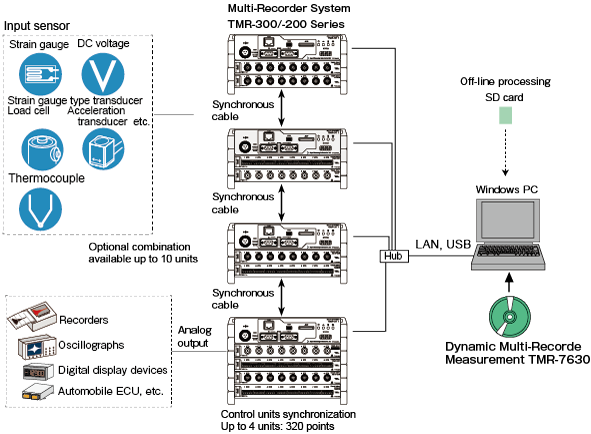

System configuration

OS / computer / interface / product key

OS Microsoft Windows 7(SP1)/8.1/10/11 Computer Any meeting specifications recommended by above OSes, CD drive

Memory: 500 MB or more

HDD space: 1 GB or more available spaceInterface USB Product key USB dongle

More Information