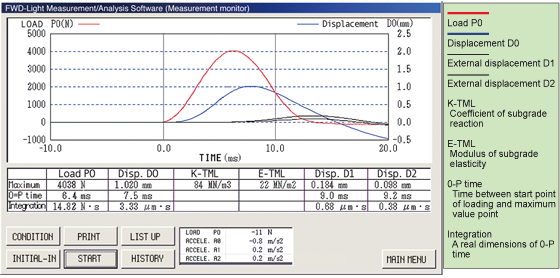

FWD-Light Measurement/Analysis software

FWD-Light Measurement/Analysis software TC-7100

This software allows control of a compact FWD from a Windows computer and analysis of measurement data. Connect to a computer with a special viewing device using RS-232C. Allows viewing of data measured and saved with a special viewing device and printing to an external printer.

- Features

- Up to 6 channels of load and deflection measurement possible

- After completing measurement, view analysis results immediately

- View, print, etc. measurement data

-

Example waveform display

-

System configuration

OS / computer / interface / PC card slot

OS Windows 7(SP1)/8.1/10 Computer Any model on which the above OSes can operate, CD drive

HDD space: 2 GB or moreInterface RS-232C (D- sub9 pin) PC card slot PCMCIA 2.1-conformant

More Information

This is a bridge box for measuring instruments, compact strain recorder DC-204R, and multi-recorder TMR-321/-323/-221/-223 using a miniplug (PRC07-P8M). Since no cable is required between the instrument and the bridge box, the instrument can be placed compactly. SB-120DD-1R and SB-350DD-1R accommodate quarter bridge 3-wire system (quarter bridge 2-wire accommodates B-B' short) and half bridge methods, and SB-120DD-4R accommodates full bridge method.

This is a bridge box for measuring instruments, compact strain recorder DC-204R, and multi-recorder TMR-321/-323/-221/-223 using a miniplug (PRC07-P8M). Since no cable is required between the instrument and the bridge box, the instrument can be placed compactly. SB-120DD-1R and SB-350DD-1R accommodate quarter bridge 3-wire system (quarter bridge 2-wire accommodates B-B' short) and half bridge methods, and SB-120DD-4R accommodates full bridge method.