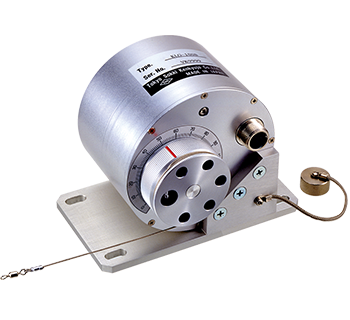

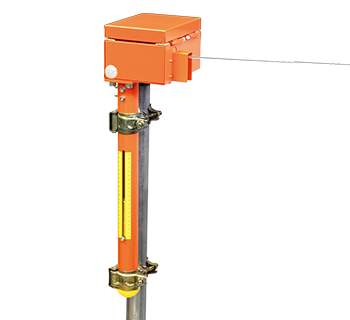

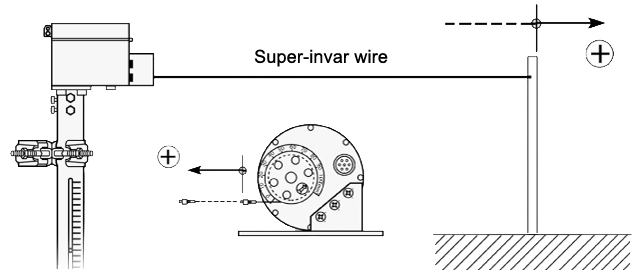

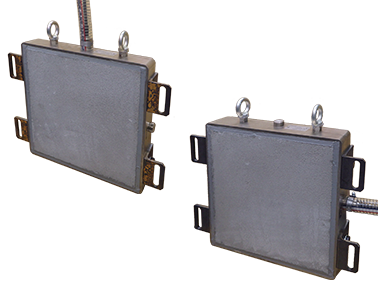

Caisson Method for Measuring Sensor KKA-PC

KKA-PC Caisson skin-friction meter 200kPa to 300kPa

The KKA-PC is a transducer to measure skin friction bearing force with the ground acting on thewall of concrete caisson. The transducer is installed so that the sensing area of the transducer faces thecaisson's wall and measures skin friction bearing force with the ground when settled and fixed.

Protection ratings : IP 67 equivalent

-

Specifications

Type Capacity Rated output Non-linearity Temperature range KKA-200KPC-U

KKA-200KPC-R200 kPa Approx. 1.5 mV/V (3000 x 10-6 strain) 1 %RO -30 to +70 ℃ KKA-300KPC-U

KKA-300KPC-R300 kPa Approx. 1.5 mV/V (3000 x 10-6 strain) 1 %RO -30 to +70 ℃ Cable Direction Capacity:200kPa Capacity:300kPa Pressure Receiving Part Top Out KKA-200KPC-U KKA-300KPC-U Pressure receiving part: Flat surface Top Out KKA-200KPC1-U KKA-300KPC1-U Pressure receiving part: R (7000<R≦12000) Top Out KKA-200KPC2-U KKA-300KPC2-U Pressure receiving part: R (4000<R≦7000) Top Out KKA-200KPC3-U KKA-300KPC3-U Pressure receiving part: R (2500<R≦4000) Side Out KKA-200KPC-R KKA-300KPC-R Pressure receiving part: Flat surface Side Out KKA-200KPC1-R KKA-300KPC1-R Pressure receiving part: R (7000<R≦12000) Side Out KKA-200KPC2-R KKA-300KPC2-R Pressure receiving part: R (4000<R≦7000) Side Out KKA-200KPC3-R KKA-300KPC3-R Pressure receiving part: R (2500<R≦4000)

More Information