Frictional Torque Sensor System

Frictional Torque Sensor System FGDH-4A

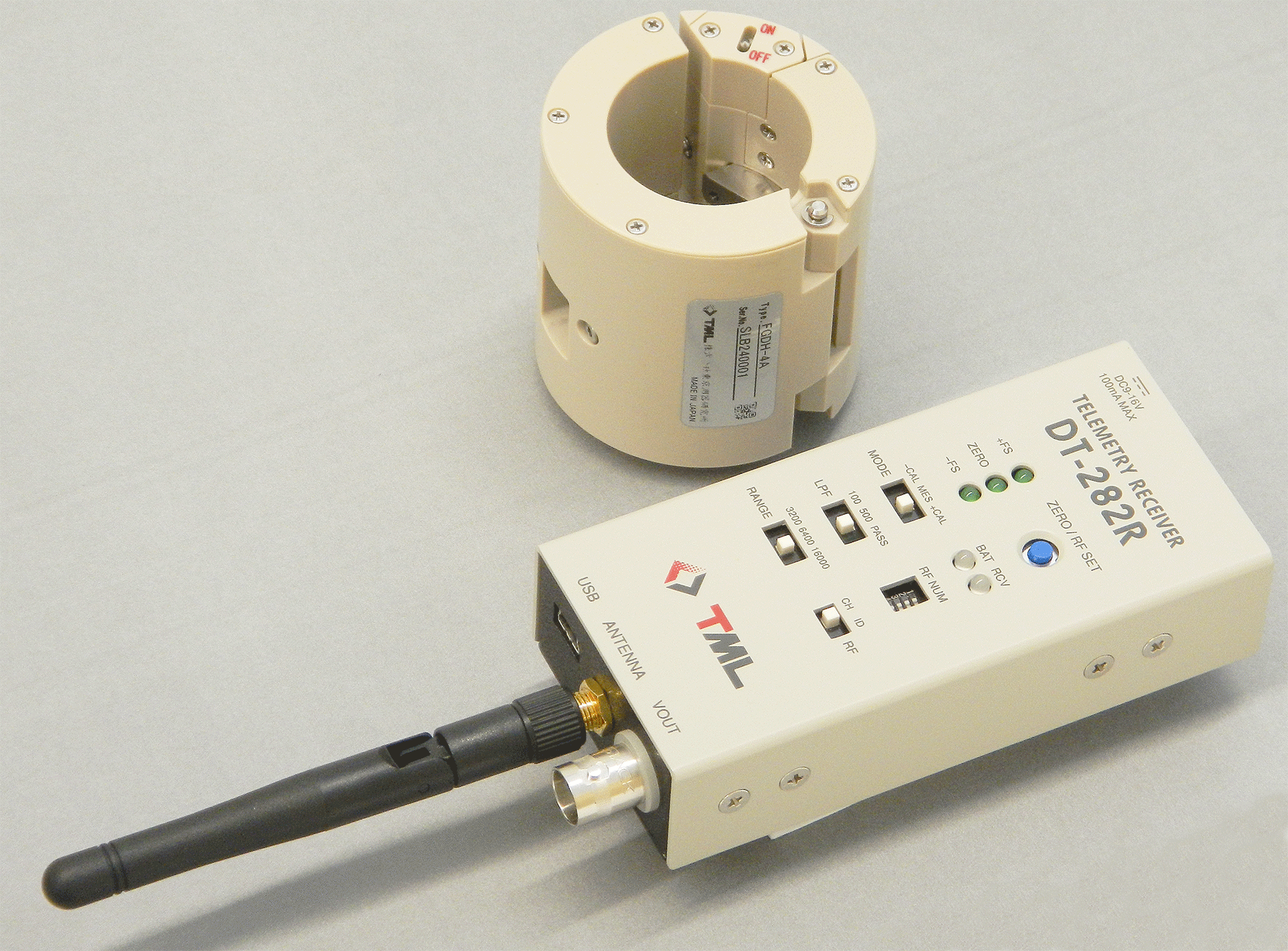

The friction-type torque sensor system FGDH-4A uses friction-type gages, eliminating the need for preparation and tedious wiring of leads to be bonded with adhesive-type strain gages. It measures the torque generated on the drive shaft of the vehicle and transmits the digital data wirelessly. The use of a 2.4 GHz low-power radio module in the radio band allows for long transmission distances and easy installation of the receiving antenna.

Installation of the sensor is as simple as clamping the shaft and fastening with screws. The applicable shaft diameter is ø20-30, ø30-40,and ø40-50mm and the power supply is rechargeable via a USB power cable, so the sensor can be recharged without having to be removed.

- Features

- 2.4 GHz band is used for wireless communication

- Applicable shaft diameter ø20-30, ø30-40,and ø40-50mm

- No bonding is required because frictional strain gauges are used

- Measurement possible immediately after clamping on the drive shaft

- Digital communication system adopted for noise-resistant measurement without wiring

- Easy-to-use rechargeable power source

- Power saving function, enabling longer measurement times than before

- Switchable between three output voltage ranges ±3200, ±6400 and ±16000 x 10-6 strain

- Can be used as a transmitter unit with 4-gauge method input

- Receiver DT-282R is dedicated to FGDH-4A

-

Specifications

Type FGDH-4A FGDH-4A-30/40 FGDH-4A-40/50 Applicable shaft diameter Φ 20 to 30mm Φ 30 to 40mm Φ 40 to 50mm Capacity Depends on the diameter (outer and inner), material, surface roughness and surface treatment of the shaft *1 Output Depends on the diameter (outer and inner), material, surface roughness and surface treatment of the shaft *1 Allowable temperature -20 to +60 ℃ (No dew condensation) Sampling frequency 5 kHz Frequency response 1 kHz Wireless specifications 2.4 GHz band advanced low power data communication system External Dimensions Φ 52 x 50 mm Φ 64 x 50 mm Φ 75 x 50 mm Weight (spacer excluded) Approx. 85 g Approx. 130 g Approx. 160 g Protection rating Equivalent to IP51 Continuous operating time Approx. 10 hours (23 ℃ ±5 ℃) Power supply Lithium secondary battery CE marking: outside the EU, compliant products are shipped only upon request.

This product is compliant with regulations in Japan, the European Union (EU), the United States, Canada, China, India, Australia, and the Republic of Korea. Please contact us for other countries.

*1:This system may not be applicable depending on the material, surface roughness or surface treatment of the shaft. Please contact us beforehand.[Test conditions]

・Torque 500 N・m ・Output *4 2500 mV (equivalent to 8000 x 10-6 strain) ・Non-linearity 1%RO (when output is 8000 x 10-6 strain) ・Conditions of test piece 1. Diameter 20 mm 2. Material SNCM439 3. Elastic Modulus 210000 N/mm2 (test result by TML) 4. Poisson's Ratio 0.29 (test result by TML) 5. Surface roughness Ra 3.2 6. Hardness HRC 38 *4: Allowable output: ±16000 x 10-6 strain (including initial unbalance of ±2000 x 10-6 strain)

Frictional Torque Sensor Protective Cover FGDHF-61/62/63

The friction type torque sensor protective cover can be easily fitted to the FGDH-3A/FGDH-4A series of friction type torque sensors and provides protection equivalent to protection class IP51. This is useful for driving tests on rough roads, etc.

- Features

- Protection rantings : IP 51 equivalent

- FGDHF-61-01, FGDHF-62 and FGDHF-63

-

Specifications

Type Compatible model Applicable shaft diameter FGDHF-61 FGDH-3A

FGDH-4Aφ20 to 30mm FGDHF-62 FGDH-3A-30/40

FGDH-4A-30/40φ30 to 40mm FGDHF-63 FGDH-3A-40/50

FGDH-4A-40/50φ40 to 50mm