Bolt strain gauge installation / calibration service

Gauge Embedding/ Calibration Service for Bolts

The bolt fastening is used in a wide range of fields in modern society and is an indispensable element. Through the measurement of axial force applied to the bolts of machine structures, automobiles, aircraft, highways, bridges, segment fasteners, and other structures, it is possible to check and control the state of fastening (checking for looseness, overtightening, and the specified fastening force). This is also utilized for the measurement of bolt strength and the bolt fastening designs. We accept gauge installation for measuring the axial force of bolts. We will machine a hole in your supplied bolts, install the strain gauges for bolts, and perform load calibration. The installation on the existing bolts enables axial force control.

Strain gauge installation service

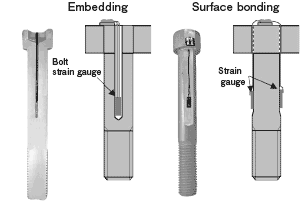

Construction with any of embedded bolt gauges or surface-adhering gauges. We can also handle special-shaped bolts upon consultation. Usable in a wide range of temperatures from low to high temperatures.

| Installation method | Embedding type | Surface bonding type | |||||

| Sensor | Embedding strain gauge | Strain gauge | |||||

| Operating temperature | -30 to +100°C | -40 to +150°C | -10 to +80°C | -40 to +150°C | -269 to +80°C | 40 to +80°C | -40 to +300°C |

| Machining | Machining hole diameter Ø0.8 |

Machining hole diameter Ø1.6, Ø2.0 |

Surface processing | ||||

| Applicable bolt | M3 or more | M6 or more | M3 or more | ||||

| others | Available with temperature measurement function | Axial force measurement, bending measurement, torque measurement | |||||

Processing method

There are two methods in strain gauge installation service. One is embedding, and the other is bonding. Choose between them according to the conditions of use.

Embedding: BTM series

A hole of 1.6mm or 2mm in diameter is drilled in the center of the bolt. The strain gauge is inserted into the hole and embedded with an exclusive adhesive. This method has the advantage of avoiding the gauge being damage by a washer, etc. while fastening the bolt.

Bonding: F, QF, ZF, CF series

Two strain gauges are bonded on both sides of the bolt shaft in axially symmetric positions to cancel the influence of bending. It is required to slightly scrape off the surface of the bolt shaft where the strain gauges are bonded, for the purpose of avoiding strain gauges being damaged while fastening the bolt or by contact of a washer. Choose strain gauges according to the usage conditions including temperature.

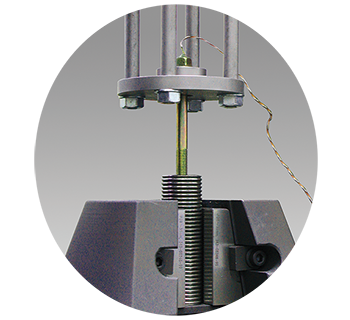

Calibration service

In order to achieve accurate measurement, we offer calibration service in which the bolt is calibrated with specified load. Instruments and calibration machines used for the calibration service are periodically calibrated and inspected by public institutions complying with the national standards.

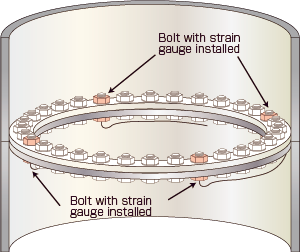

Application example

Wind turbine generator facilities are aimed at enlargement in the scale. Management of axial force is indispensable for the bolts used in joint parts of the structures, both in assembling process and in actual working condition. It is possible to continuously monitor the axial force by installing bolt strain gauges in some of the bolts used in the joint part.

More Information