Strain Gauges for Transducers

FCT Series

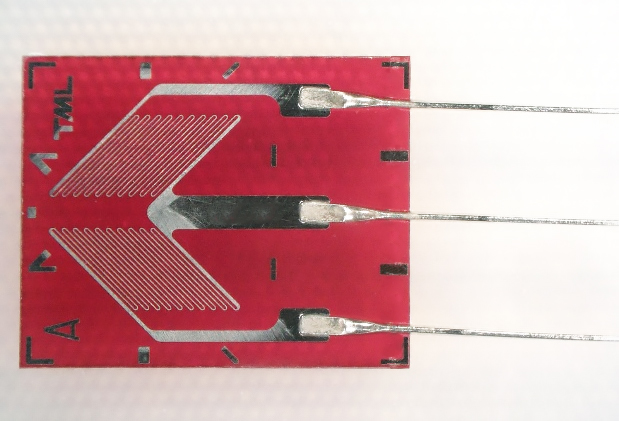

The conventional model, FCT-2-350, featured four gauge leads and was composed of two strain gauges, each arranged at a 45°angle and configured in a quarter-bridge circuit.

The newly added products feature a half-bridge configuration (two-gauge system) with three gauge leads.

This simplifies the bridge wiring and improves work efficiency by reducing the number of lead wires.

While some 45°-oriented strain gauges, such as the FLT-1 series, use a single sensing element, the FCT series employs a design with two strain gauges arranged side by side at 45°, making it easier to integrate into bridge circuits.

By adopting the half-bridge structure, the new design offers greater efficiency and ease of handling.

| Type | Uniaxial, 2-element (for torque measurement) | |

|---|---|---|

| Sensing Element | Material | Cu-Ni Alloy |

| Material | Material | Special Plastic |

| Gauge Leads | Material | Silver-Plated Copper Wire |

| Conductor | 1/0.14 | |

| Round-Trip Resistance per Meter | 2.5Ω | |

| Length | Approx. 25mm | |

| Solder | Lead-Free Solder | |

| Surface Protection | Polyester Film | |

| Creep Code |

A, C, E, G, I, K, M, O, Q, S, U, W |

|

| Measurement Target Materials | 11: Mild Steel 17: Stainless Steel 23: Aluminum |

|

| Operating Temperature Range | -30 to +150℃ | |

| Temperature Compensation Range | +10 to +100℃ | |

| Recommended Allowable Current | 30 mA or less (for metallic measurement target materials) | |

| Strain Limit*1 | 5%(50000με) | |

| Fatigue Life*2 | 1×106 cycles | |

*1 Strain limit is based on results at room temperature

*2 Fatigue life is based on results at room temperature with a strain level of ±1500 με (15 Hz)

-

Single-element

Single-element

Gauge pattern Type Gauge length

(mm)Gauge width

(mm)Backing length

(mm)Backing width

(mm)Resistance

(Ω)

FCT-2-350-A-11-F

FCT-2-350-A-17-F

FCT-2-350-A-23-F2 1.5 7 5.6 350

Creep Compensation

Stable and high-precision creep characteristics are essential for strain gauge-type transducers. Generally, creep compensation is achieved by offsetting the creep of the elastic body (positive) and the creep of the strain gauge (negative). Our product allows for high-precision creep compensation by finely categorizing the turntab dimensions and identifying them with a creep code.

| Gauge creep |

|

|

|---|---|---|

| Creep code | New Product |

|

| Existing Product |

|

|

Features

- Torque strain gauge for transducers with creep code

- Half-bridge configuration

- Gauge leads oriented in the same direction for easier terminal wiring

- Gauge length: 2 mm

- Gauge resistance: 350 Ω

- 12 creep code patterns available: A, C, E, G, I, K, M, O, Q, S, U, W

- Lead-free solder specification (CE compliant)

FLAB Series

Our finely tuned creep compensation enables shorter development times for high-precision transducers, making it easier to achieve superior performance with strain gauge-based designs.

The FLAB series supports temperature compensation for materials with thermal expansion coefficients of 11, 17, and 23 ppm/℃. It also allows accurate strain measurement as a direct replacement for conventional creep codes C2, C4, C6, and C8.

| Type | Single-element | |

|---|---|---|

| Sensing Element | Material | Cu-Ni Alloy |

| Gauge Base | Material | Special Plastic |

| Gauge Leads | Material | Silver-Plated Copper Wire |

| Conductor | 1/0.14 | |

| Round-Trip Resistance per Meter | 2.5Ω | |

| Length | Approx. 25mm | |

| Solder | Lead-Free Solder | |

| Surface Protection | Polyester Film | |

| Creep Code |

A, C, E, G, I, K, M, O, Q, S, U, W |

|

| Measurement Target Materials | 11: Mild Steel 17: Stainless Steel 23: Aluminum |

|

| Operating Temperature Range | -30 to +150℃ | |

| Temperature Compensation Range | +10 to +100℃ | |

| Recommended Allowable Current | 30 mA or less (for metallic measurement target materials) | |

| Strain Limit*1 | 5%(50000με) | |

| Fatigue Life*2 | 1 × 106 cycles | |

*1 Strain limit is based on results at room temperature

*2 Fatigue life is based on results at room temperature with a strain level of ±1500 με (15 Hz)

-

Single-element

単軸

Gauge pattern Type Gauge length

(mm)Gauge width

(mm)Backing length

(mm)Backing width

(mm)Resistance

(Ω)

FLAB-2-350-A-11

FLAB-2-350-A-17

FLAB-2-350-A-232 2.9 6 4.5 350 FLAB-3-350-A-11

FLAB-3-350-A-17

FLAB-3-350-A-233 2 7 3.8 350 FLAB-6-350-A-11

FLAB-6-350-A-17

FLAB-6-350-A-236 2.6 10.6 4.5 350

Creep Compensation

Stable and high-precision creep characteristics are essential for strain gauge-type transducers. Generally, creep compensation is achieved by offsetting the creep of the elastic body (positive) and the creep of the strain gauge (negative). Our product allows for high-precision creep compensation by finely categorizing the turntab dimensions and identifying them with a creep code.

| Gauge creep | Large → Small | |

|---|---|---|

| Creep code | A > C > E > G > I > K > M > O > Q > S > U > W | |

Features

- Uniaxial strain gauges for transducers with creep codes

- Gauge lengths: 2 mm, 3 mm, and 6 mm

- Gauge resistance: 350 Ω

- 12 creep code patterns available (A, C, E, G, I, K, M, O, Q, S, U, W)

- Lead-free solder specification (CE compliant)

More Information